R&D

Research & Development

Research and Development (R&D) serves as the bedrock for innovation and advancement within any organization. It is the dynamic process of exploring new horizons, experimenting with cutting-edge technologies, and conceptualizing novel ideas to drive product and process improvements. Through a blend of meticulous analysis, creative thinking, and technological exploration, R&D fosters the creation of pioneering solutions that not only meet the current market demands but also anticipate and shape future needs. By continuously pushing the boundaries of knowledge and technology, R&D paves the way for transformative breakthroughs, ensuring sustainable growth, and fostering a competitive edge in a rapidly evolving business landscape.

FASPAC INNOVATION

Surface Grinder Machine

A surface grinder machine is a vital tool in creating impeccably smooth finishes on flat surfaces. This prevalent abrasive machining process involves a rotating wheel coated in coarse particles that precisely chip away at metallic or nonmetallic materials, ultimately resulting in a precisely flattened or smoothed surface.

Milling Machine

Milling machines play a pivotal role in the machining process, employing rotary cutters to meticulously eliminate material by propelling a cutter into a workpiece. This can occur in different directions across one or multiple axes, with adjustments made to the cutter head speed and pressure, enabling precise and efficient material removal.

Hydraulic Cylindrical Grinding Machine

A cylindrical grinder represents a specialized grinding machine utilized for contouring the external and internal surfaces of an object. With the ability to handle various shapes, this grinder requires the object to possess a central axis of rotation, accommodating forms like cylinders, ellipses, cams, and crankshafts, among others.

Honing Machine

A honing machine serves the primary purpose of manufacturing new and refurbishing used Tungsten Carbide dies, particularly within the size spectrum of 1 mm to 15 mm. Operating on a unique principle, it enables the grinding and polishing of the die angle and bearing length within a singular setup. This distinctive feature ensures the production of flawlessly concentric dies, guaranteeing precision and consistency in the manufacturing process.

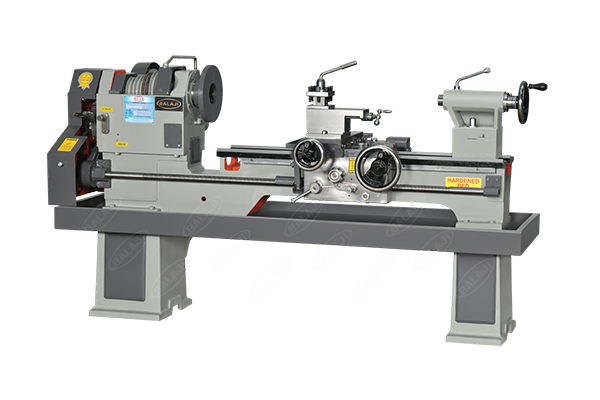

Lathe Machine

A lathe machine is an instrumental tool that revolves a workpiece around an axis of rotation, facilitating a range of operations including cutting, sanding, knurling, drilling, deformation, facing, and turning. This process utilizes tools applied to the workpiece to produce an object characterized by symmetrical features around the rotational axis, ensuring precise and uniform results.

Universal Tool & Cutter Grinder Machine

A tool and cutter grinder serves the crucial function of sharpening milling cutters, tool bits, and a myriad of other cutting tools, making it an incredibly versatile machine for an array of grinding tasks. Operating this machine, especially the manual variant, demands a high level of skill, requiring an understanding of the interplay between the grinding wheel and the material being cut, as well as an adept knowledge of tool geometry. Given the vast diversity in shapes and types of machining cutters, its usage necessitates flexibility. The longitudinal and lateral movement of the table, coupled with the swiveling and adjustable head in the horizontal plane, as depicted in the accompanying image, allows for the attainment of the crucial clearance angles imperative for various cutters.